Bunker Renovation and Restoration Creates Impact

Bunkers are unique and different when it comes to renovation and restoration projects.

The majority of clubs or courses want to maximize their dollars spent. The days of build it and they will come or spend it on the work and see what happens, are gone. Everyone in ownership or leadership or in membership groups want to get the biggest bang for the buck these days.

Work on the greens is very expensive, and also disruptive to play. Does that mean you should not renovate your greens? Absolutely not, but clubs and owners start to balance things and look to maximize the dollar. With bunkers they can get the instant impact.

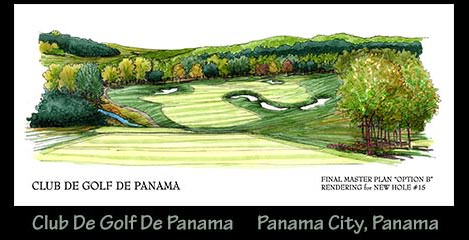

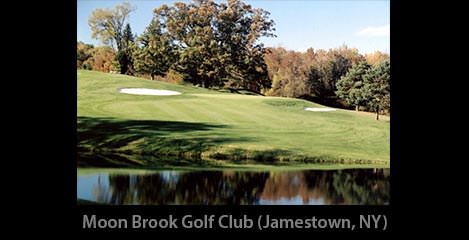

It’s visual impact. You have all these green zones, or green hues on the golf course with the fairways, primary rough, secondary rough, collars, greens, tees – it’s a sea of green out there. And then you have a light tan element, and it immediately grabs your attention, directs you and sometimes intimidates you. It is powerful in that way. That gives you that instant impact when you restore or renovate and even add bunkers.

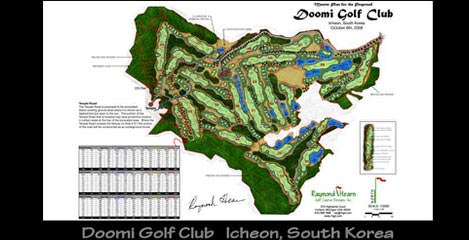

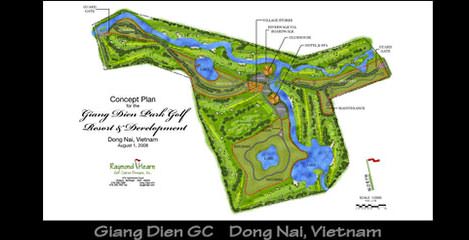

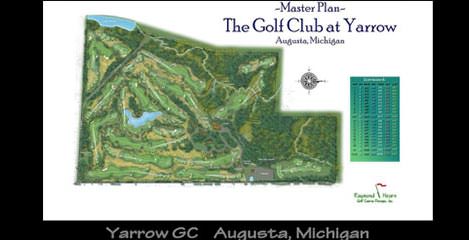

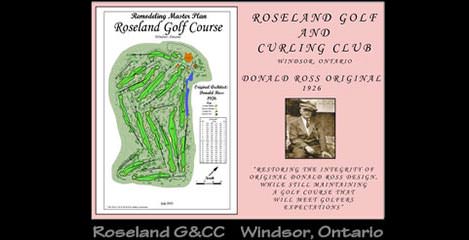

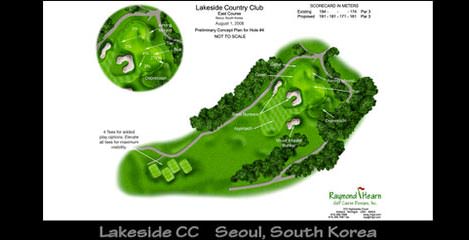

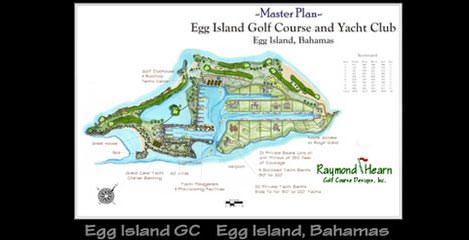

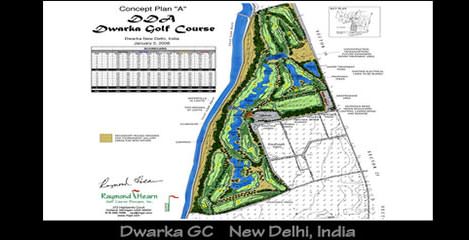

Every bunker Raymond Hearn Golf Designs creates is different, yet they all have to fit the site, the historical context, if they have history, and they have to fit the expectations of the members or owners.

How we go about the process is always the same, and it is in seven steps:

- Step one, we sit down and listen. They will tell me what to expect, what the problems are with the bunkers. And there are clubs that have better players involved and they want to comment on the strategy associated with the bunkers. Basically problems, likes and dislikes, are communicated.

- Step two, I go out and play and study the course and I do this multiple times.

- Step three, I then can speak intelligently with the club president, committee chairs, or owners (in case of public), golf course superintendents, general managers and golf professionals, or what is usually the big five at most facilities. I ask them what do you really want to accomplish?

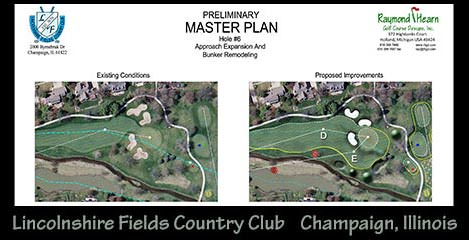

- Step four involves preliminary designs from each key part: strategy, shot value, playability, depth perception and aesthetics. I also provide a preliminary cost at this step.

- Step five: After step 4 is approved, I complete very detailed construction drawings (some of the most comprehensive in my industry).

- Step six is to get bids on the construction drawings and then award the preferred contractor bid.

- Step seven is starting construction.

That’s the process. A lot of clubs and golf course superintendents, architects, directors of golf, will break proposed projects down to green design, tee design, fairway design, bunker design and then trees and water hazards. In the end it is clearly how they all look together and fit together, so the big picture must always be kept in mind.

One thing I see, especially in the Midwest, are many articles on how expensive bunkers are to construct and then maintain. It puts the onus on operations. If after a rain all your sand is at the bottom of the bunker and contaminated with mud, then it is a lot of work to get the sand separated from the mud and raked back up the faces. It’s a lot of maintenance and takes a lot of time.

In construction now there is something remarkable that helps with this – new improved bunker liners.

Two that are great in the Midwest and Northeast, right now, are the Better Billy Bunker Liner and the Concrete Capillary Bunker Liner. Currently our firm has five projects involving bunkers, and all five are going with these new improved bunker liners. This has been consistent for the last seven years.

What they do is hold the angle of repose of the bunker sand – they don’t allow it to slide all the way down in the majority of most rain events, which is absolutely incredible. They have revolutionized bunker construction and lessened bunker maintenance.

Why don’t more courses do this? I scratch my head and ask myself that often.

Yes, it is a capital improvement cost, but if clubs start doing cost-benefit analysis they have to include how much the maintenance crew is costing in time spent fixing washouts in bunkers. How much time does it take to get the mud from the contaminated bunker sand? How much cost to replace the sand? How much money are you losing in disappointing members or golfers who may quit the club? A big outing is coming, the course is ready to show, and then the rain comes and the bunkers are not going to impress anybody. What signal does that send?

In the real big picture, and every club ponders this: Do they cut expenses so they can lower membership fees and gain more members? That seldom works. It isn’t a sure way to generate more value. It is digging a grave – slowly.

In our experience the key to success is finding a way to reinvest and reinvent and, in the end, create more value and a better bottom line.

We know there is threshold. You can’t be pompous in the process and ask the club to cross that threshold of what they can afford to do. But there is a Golden Rule in place. No matter the financial status, it is important to perhaps improve one or two bunkers a year with a better liner, better sand, edge relocation. Just doing a bunker or two each year gives golfers something to talk about and in the end realize wow, we’ve done this and improved our golf course. It can be as little as one bunker per year, or more, but the key is doing it in phases. Start with the bunkers that present the most significant maintenance challenges.

In the bunker projects we are doing now all have the same goal. They want to excite current members (private) or golfers (public) while attracting new members/golfers, and lessen the maintenance cost of those bunkers, which will generate more net revenue.

Amidst the sea of green hues on a golf course those beautiful tan features stand out visually while impacting golfers in so many positive ways! Some bunker redesign may be just what your club needs in terms of increasing your bottom line.